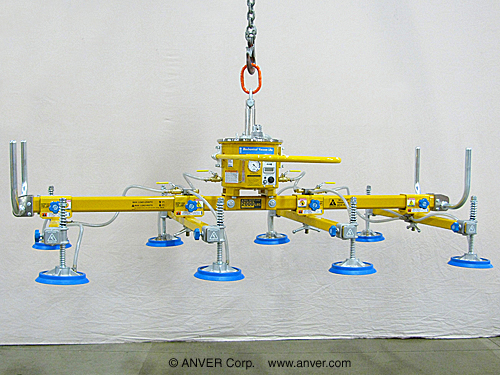

Unitcarrying Capacity

Metal thicknessAcoustic safety warn system, incl. batteryBall valves that shut off individual suctioncups - factory standard. Other featuresVacuum meter and vacuum meter

We can provide an ergonomic vacuum lifting system for special environments including food grade, pharmaceutical, explosive or hazardous work areas, wash down, and dirty environments. Vacuum lifts integrated with ergonomic PIVOT PRO cranes make a great system that is both easy for workers to use and cost effective.